|

Our company

S. Agostino S.p.A is a

private company leader in the field of rolls and rings

for the steel and non-ferrous industries since 1956.

The experience we have

gained assure the most efficient and top quality rolls

for rolling mills.

Our manufacturing range

is the following:

• rolls for reinforced

concrete round and wire rod mills (open and continuous

design)

• rolls for section and

bar mills (open and continuous design)

• rolls for billet,

medium-size and large section mills

• rolls for flats in the

line stands and continuous mills

• rollers for

straighteners, pinch-rolls and rolls mills for piping

• rolls for calanders

and mixing mills (rubber, resin, plastic, PVC, paint,

soap, paper)

• rolls for working

cereals and alimentary

• shells for brick-kiln

machines

• pistons

Our production includes

rolls and rings in hypereutectoid steel, indefinite and

clear chill cast iron, nodular pearlitic and acicular

cast iron.

The sales network is

expanding on the national and international market

thanks to the competitivity of our product. In Italy and

abroad we supply all steel producers and constructors of

rolling mills, for steel, rubber, plastic and

brick-kiln-machines, we export above all to Europe . the

Far Est. the USA , Canada and South America .

Our Service Department,

available before and after sales, assures all the

technical support which is necessary for the selection

and optimum utilization of rolls. It also focuses on the

analysis and development of research topics intended to

meet the growing and innovative requirements of rolling

mills.

The Quality Certification

obtained in 1994 (UNI EN ISO 9001:2000) and the

experience acquired over the years, guarantee the

absolute qualitative constancy of the product.

FOUNDRY

Our Foundry was the first

in Italy to install electric induction furnaces designed

to produce rolls. In particular, it has 3 electric

induction melting furnaces for liquid preparation of 6

and 15 tons and gas furnaces for heat treatments: all

furnaces are automatically controlled by PLC.

Only top quality raw

materials are used to charge melting furnaces.

We also make use of

mechanized plants for the preparation of sands and of

automatic machines for flask moulding. The productive

capacity amounts to 8.000 tons a year.

MACHINE SHOP

The

machining is made in 2 different roll shops; one is

directly connected to the Foundry by roller conveyors

for transferring rough castings to Machining Department.

We have numerical control lathes, boring and grinding

machines as well as knurling machines for rebar and

perforating machines for central and peripherical holes

which can supply the Customers with rolls ready for use.

The productive capacity

amounts to 5000 tons a year and is based on equipment

which can produce rolls with a maximum diameter of 1200

mm .

Non destructive tests are

carried out on each type of roll during the production

cycle.

CHEMICAL

METALLOGRAPHIC LABORATORY

The lab has a

spectrometer which can carry out chemical analysis in

real time on the specimens taken during the preparation

of the liquid in melting furnaces as well as on the

samples taken from rolls for production control.

The spectrophotometer is

used for special analysis and for characterization of

ferroalloys; moulding sands are controlled by adequate

devices.

Metallographic tests are

carried out on produced materials by means of an optical

microscope which can verify the conformity of

structures.

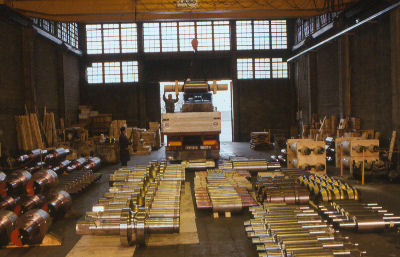

INSPECTION AND

SHIPPING

Completely finished machined rolls included central and

peripherical holes, crossing and convex grinding are

transferred by roller conveyors from the Machine Shop to

the Inspection and Shipping Department.

The final inspection

includes: dimensional controls, hardness, ultrasonic

test, roughness, and any other control required by the

Customer.

The roll number assigned

at the beginning of the production cycle is now stamped

on the roll so as to identify the product speedly and

correctly.

Painting and packing

represent the final steps of the production cycle which

is completed by shipping.

|